I did a bit of polishing on the various components inside the receiver but did not find the source of the problem as the cartridges are still being scratched.

With the 45-70, I do expect to see recoil generated wear on the magazine tube at the cutout where the retaining screw passes between the barrel and the tube. Both barrel and tube have the recess but the tube is what will take a lick'n. Marlin learned this with the early 444 and moved away from the band to an end cap on the forearm. JES Reboring will rebore/rechamber any Marlin 336 to 444 Marlin but recommends only models with the forearm cap be used.

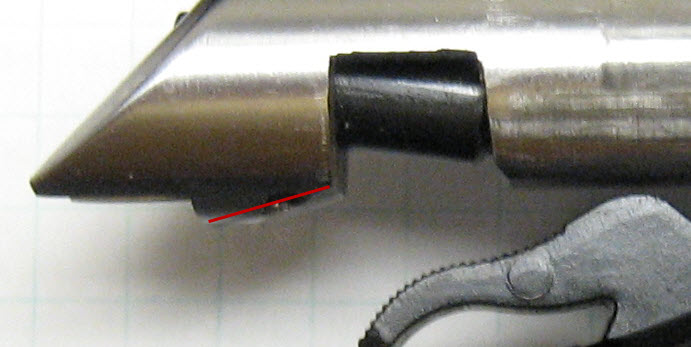

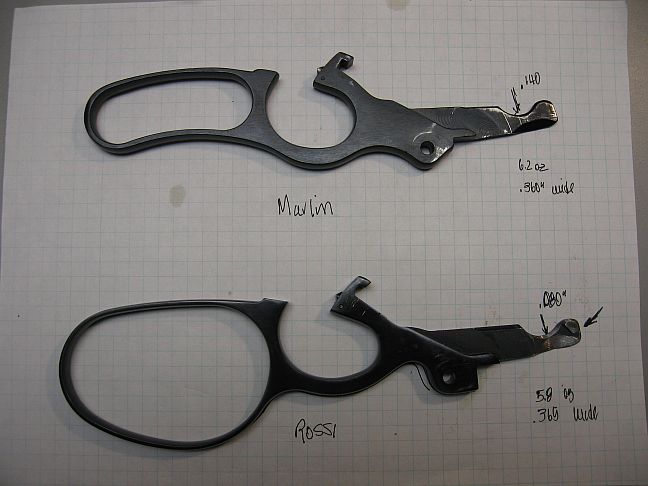

You can see a light break in the tube on my rifle, not really a problem as I have some early 444s that look like this but it has been my experience that the cutout must be perfectly aligned to minimize wear. I check this on any 336 that comes into my possession and most need the base of the tube trimmed to bring them into alignment. There is no cure for a tube that is too short. Here is the mismatch on the Rossi.

Filing the base of the tube to slowly bring the cutouts into alignment.

Rossi has seemed to make a number of improvements to small parts. All the parts are made by BrazTech, nothing come from outside of the Company. For instance only solid pins are used, no roll pins. One neat change is on the bolt is that the rear firing retaining pin, a roll pin on the 336, has been changed to a threaded Allen plug. That is really neat.

Back to the scratches on the case. It relates to what I mentioned in my last post concerning the aft portion of the bolt as it starts it forward movement across the upper radius of the hammer. The aft portion of the bolt is pressed up and in response the forward portion to the bolt is pressed down against the carrier. This pressure seems to cause the carrier to bind as it tries to drop. The cartridge is caught in the middle. My question for the Rossi guys is could the main spring be causing this unnecessary pressure? Is this the principle issue with the '92, and an issue that Steve Gunz kit solves?

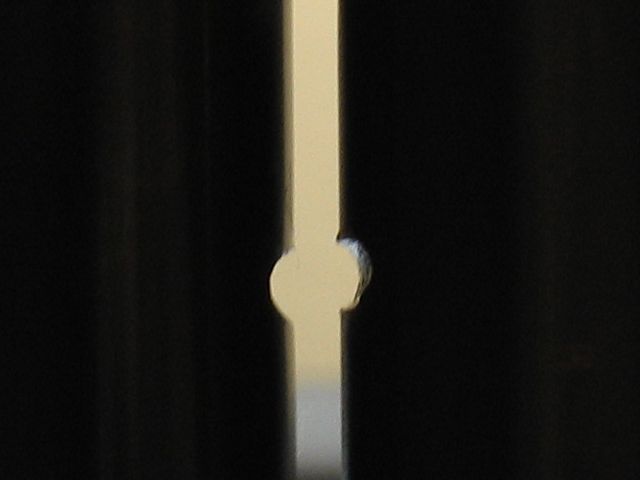

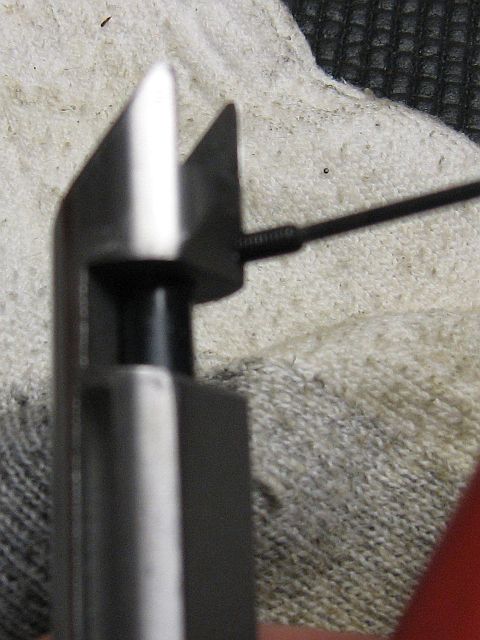

This pressure on the bolt also causes me concern with the wear on the lever. Back to the image in last post.

Notice that the portion that passes through the bolt is quite a bit lighter than a 336. The only effort in another wise smooth action is the effort to get the bolt beyond mainspring pressure but that effort might ultimately cause wear on this portion of the lever. Your comments are appreciated? I do not know Nate Kiowa Jones but if he wasn't a six hour drive from me I would have already been knocking at his shop door as I've not been able to find any comments in detail about the RG series yet, only the '92.

Please also note that this is not an expression of dissatisfaction with the firearm, Rossi has sold me as the RG is exactly what I hoped it would be.